Ferritic Nitrocarburizing (FNC)

ECM Flex Vacuum Furnace

Ferritic Nitro-Carburizing (FNC) is a thermochemical surface hardening process using diffusion of both nitrogen and carbon into the heat-treated part. This treatment is mainly used to improve wear and fatigue resistance along with enhancing resistance to corrosion. Low-alloy steel parts are most suitable for this process.

Nitrocarburizing (FNC) using a Flex vacuum furnace system not only improves surface hardness qualities, but significantly reduces cycle time, optimizes energy consumption, and improves thereby increasing productivity. In comparison to a standard Nitriding process, it also takes much less time to achieve case depth requirements, mainly in part due to the addition of carbon to achieve faster diffusion.

• Drivetrain parts (wear plates, washers, clutch plates, gas/brake pistons, ball pivots/joints, pneumatic lift pistons, brake rotors)

• Firearm components (barrels, slides, differential cases)

• High pressure castings (engine blocks, bell housings, transfer cases)

• Tooling applications

Nitrocarburizing treatment of housings reduce space requirements by limiting use of washers and pins. This treatment provides resistance to wear and adhesion on the surface of the housing that might come into friction with rotating gears or pinions. These pinion shafts (used in a differential assembly) are also highly prone to wear because the gears placed onto the shaft rotate the surface. When nitrocarburizing on a pre-treated material (e.g. 4140; for acceptable mechanical strength), you will see improved anti-seizure resistance.

More than 80% of vehicles currently delivered in USA and Canada are equipped with FNC-treated brake discs

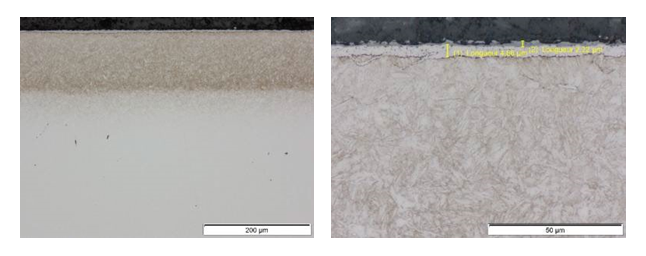

Diffusion layer between 0.1 and 0.15mm

Surface hardness higher than 800Hv (1050Hv measured)

• Reliable, consistent retort temperature does not cool during process operation

• Separate heating & cooling chambers to expedite throughput

• Improved mechanical properties, corrosion resistance and fatigue strength

• Increased efficient process repeatability & uniform production flow

• Positive workload movements via lift-and-carry (never push/pull)

• Full workload transport to/from the Flex is available

• Eco-friendly electric heating

• Thermal afterburning after vacuum pump - encapsulated/one TNV per line

| Condition | Flex Vacuum Furnace | Standard System |

| Heating Time (to 580°C) | 45 min. | 90 min. |

| Energy - Load | 45 kWh | 45 kWh |

| Energy - Muffle | 60 kWh (only for the first heat up) | 60 kWh |

| Process Time | 120 min. | Same |

| Cool Down Energy - Muffle | 0 kWh (no cooling of the muffle) | 40 kWh |

| Cool Down Energy - Load | 10 kWh and 14 Nm3 N2 | 100 kWh |

| Cooling Down Time | 5-15 min in hidden time | 3 hrs. |

| Opening/New Load | 5-15 min in hidden time | Same |