ECM Lab Solutions is dedicated to laboratory, university, and research & development heat treat solutions for the crystal growth, photovoltaic, and semiconductor industries. It gathers products from several ECM Group subsidiaries under one brand (ECM Technologies, SEMCO Technologies, ECM Greentech: Jipelec, Cyberstar).

Not sure which product is best for your heat treatment process? Contact us and we will help you determine which furnace is right for you.

Semiconductor Wafer Processing Furnaces

SEMCO semiconductor furnaces for diffusion, oxidation, doping, and other processes in wafer and cell manufacturing (4”, 6”, 8” and 12” wafers).

CrystalMax ‘Cast-Mono’ Furnaces

• Solar crystal growth furnaces

• Mass or lab production DSS furnace

• Compatible with M4-M6-M12 wafers

• High cell efficiency PERC/TOPCON

• High reliability, reproducibility & flexibility

RTP/RTA Wafer Thermal Processing Furnaces

Annealsys & Jipelec rapid thermal processing & annealing furnaces provide fast heating and cooling to process temperatures of ~200-1300°C (with ramp rates typically 20-200°C/sec). Excellent gas ambient control for multistage processes within one processing recipe.

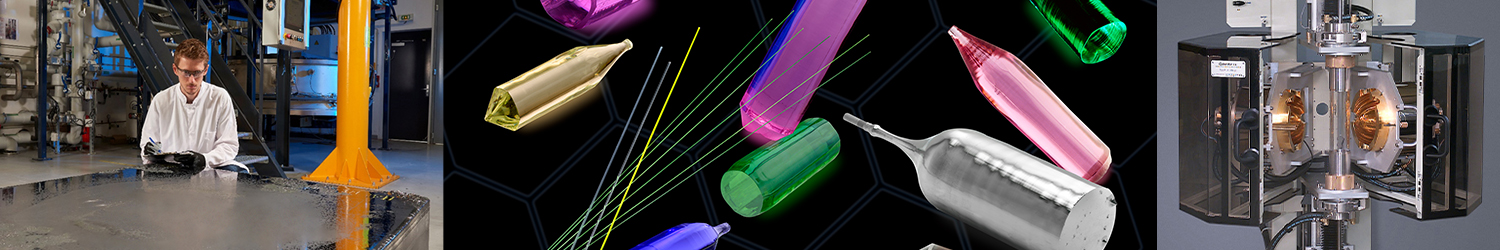

Cyberstar Crystal Growth Equipment

Cyberstar manufactures cost effective crystal growth equipment like Czochralski, Bridgman, floating zone, liquid phase epitaxy and, mirror furnaces (infrared or laser heating).