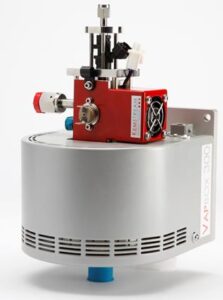

Kemstream

ALD & CVD Direct Liquid Injection (DLI) Vaporizers

KEMSTREAM manufactures innovative and advanced Direct Liquid Injection (DLI) vaporizers and atomizers for CVD, MOCVD, MOVPE, ALD, spray pyrolysis and all gas phase processes and precursors. They deliver pure, accurate, repeatable and stable vapors and aerosols flows.

KEMSTREAM also manufactures accessories for DLI vaporizers and atomizers:

• Liquid panels especially designed for feeding DLI vaporizers with air sensitive

and/or moisture sensitive precursors, either pure precursors or precursors

dissolved in an organic solvent

• Temperature Control Units (TCU)

• Gas panels for feeding DLI vaporizers with carrier gas

KEMSTREAM can also do injection/vaporization tests in CVD/ALD processes conditions on a dedicated test bench equipped with a Vapbox and featuring flows, pressures and temperatures monitoring system. Contact us to schedule a test today!

• The liquid and the carrier gas are mixed before injection in the vaporization chamber to allow for an efficient mix of the two fluids

• The liquid and the carrier gas are mixed before injection in the vaporization chamber to allow for an efficient mix of the two fluids

• The mixture injector injects a mixture of liquid and carrier gas in the vaporizer

• The depressurization of the mixing chamber in the vaporization chamber generates a blasting effect on the co-injected liquid that is atomized in the heated vaporization chamber as a mist (aerosol) of small droplets.

• The aerosol generated maximizes the total exchange surface between the liquid phase and the gas phase. It allows optimized heat transfer to the droplets from the hot walls of the vaporizer and through the carrier gas that serves as a heat transfer media. Non-contact type flash vaporization is achieved.

• The pulsed injection generates turbulences inside the vaporization chamber which help optimized heat transfer and intimate mix of the generated vapors with the carrier gas (vaporization requires heat transfer).

• ALD and CVD of high k oxides / as capacitive materials (gate oxide, DRAM, MIM, super-capa, etc) Ta2O5, TiO2, ZrO2, HfO2, HfySiyOz (HfSiO), HfxZr1-xO2 (HfZrO2), HfwLaxOyNz (HfLaON), SrTiO3 (STO) BaTiO3 (BTO)

• CVD and ALD of electrodes / (gate, DRAM, MIM, super-capa, etc) Pt, Co, Ru, TiN, TaN, SrRuO3, WC, TaxCy, WwTixCyNz (WTiCN)

• CVD and ALD of catalytic materials / metals (Pd, Au, Ir, etc), oxides, nitrides, etc

• MOCVD of III-V and II-VI semiconductor materials / Nitrides, selenides (CISe, CIGSe), sulfides (CIS, ZnS, In2S3), SiC, etc

• CVD of phase change materials for PCRAM applications / Multi-metallic alloys, tellurides (GST)

• CVD of Li containing materials for batteries applications / LIPON, Li3PO4, Li containing oxides

• CVD of ferroelectric materials for FeRAM applications / SBT, PZT, BiTi

• CVD of piezoelectric materials for MEMS applications / PZT, PLZT

• CVD of complex multi-metallic oxides / 2G REBCO High Temperature superconducting materials, multi-metallic oxide catalysts

• MCVD, FCVD, PCVD, OVD, VAD , FHD and FAD of optical fibers preforms and waveguides / Lanthanides and transition metals doped optical fibers (silica), sulfide and selenide glasses

• CCVD of carbon nanotubes / MWCNT

• iCVD of polymers / organic ones

• CVD of 2D semiconductors / MoS2, WS2, MoSe2, WSe2, etc

• PECVD and ALD of optical materials / TiO2, Nb2O5, Al2O3