Cristal

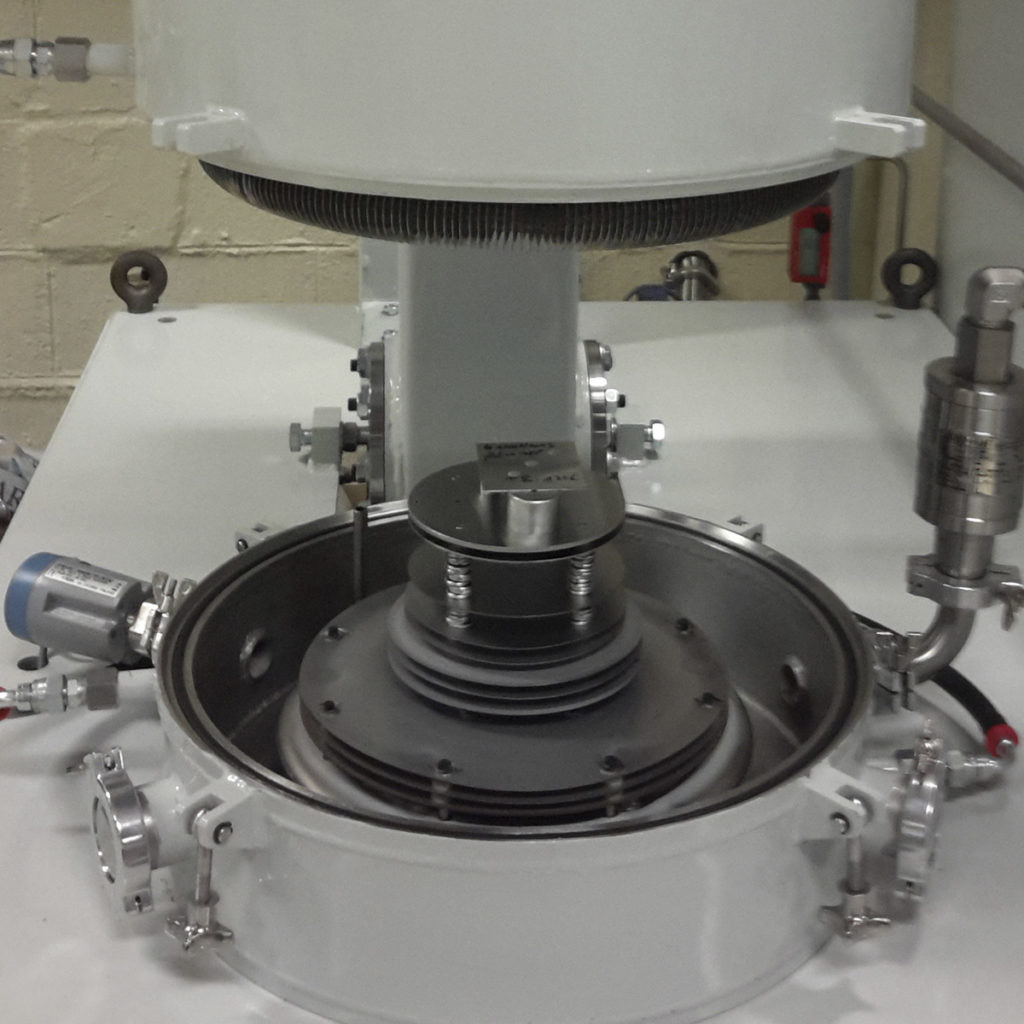

MOLECULAR VACUUM BELL FURNACE FOR HIGH TEMPERATURE TREATMENTS

Cristal furnaces are dedicated to heat treating under vacuum at high temperatures. The enclosure is insulated with specific metals, with a possible choice of molybdenum or tungsten resistors. It is the perfect tool for clean treatments at high temperature. Its design allows precise positioning of loads. The patented resistor design ensures exceptional precision while piloting your process.

The Cristal range heat treats pieces under vacuum with a wide range of working temperatures. Depending on the selected heating elements, working temperatures allow heating up to 2300°C.

Cristal furnaces also adapt to an array of applications and provide clean treatments, at high temperatures. Loading is simplified by an easy access to the hearth, and ensures a precise positioning of parts.

• Tempering

• Magnetic annealing

• Bright annealing

• Hyper quench hardening under gas

• Degassing

• Sintering

• Glass to metal sealing

• Metal ceramic brazing

• Brazing under vacuum

• Stainless steel

• Aluminium alloys

• Super alloys

• Titanium alloys

• Refractory metals

| Specifications | ||

| Model | Length | Height |

| 40-60 | 400 | 600 |

• Metallic hot zone up to 2000°C

• Heating elements make of W

• Hot zone insulation made of W + Mo

• Vacuum: 10-2 mbar

• Pit Type: Allows access on 3 sides with automation

OPTIONS

• Secondary vacuum

• Wet or dry hydrogen

• Accelerated cooling

• Gas panel (Nitrogen, Argon, Hydrogen)

• Pressure regulation