Service, Maintenance & Aftersales

AFTER SALES SERVICE: Committed to your Success ECM Technologies fully supports your project before and after initial installation:

ECM Technologies fully supports your project before and after initial installation:

• After sales support available 24/7 all over the world

(subsidiaries in China, India, Germany and USA)

• Test and diagnosis platform

• International stock of spare parts ready for shipment

• Fast delivery for optimal productivity

Our range of services include:

• Training, installation and start-up

• Remote maintenance

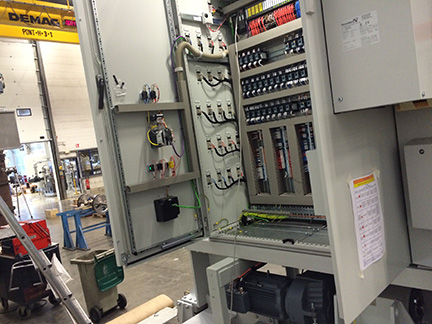

• On-site preventive and corrective maintenance

• Leak search, calibration, TUS

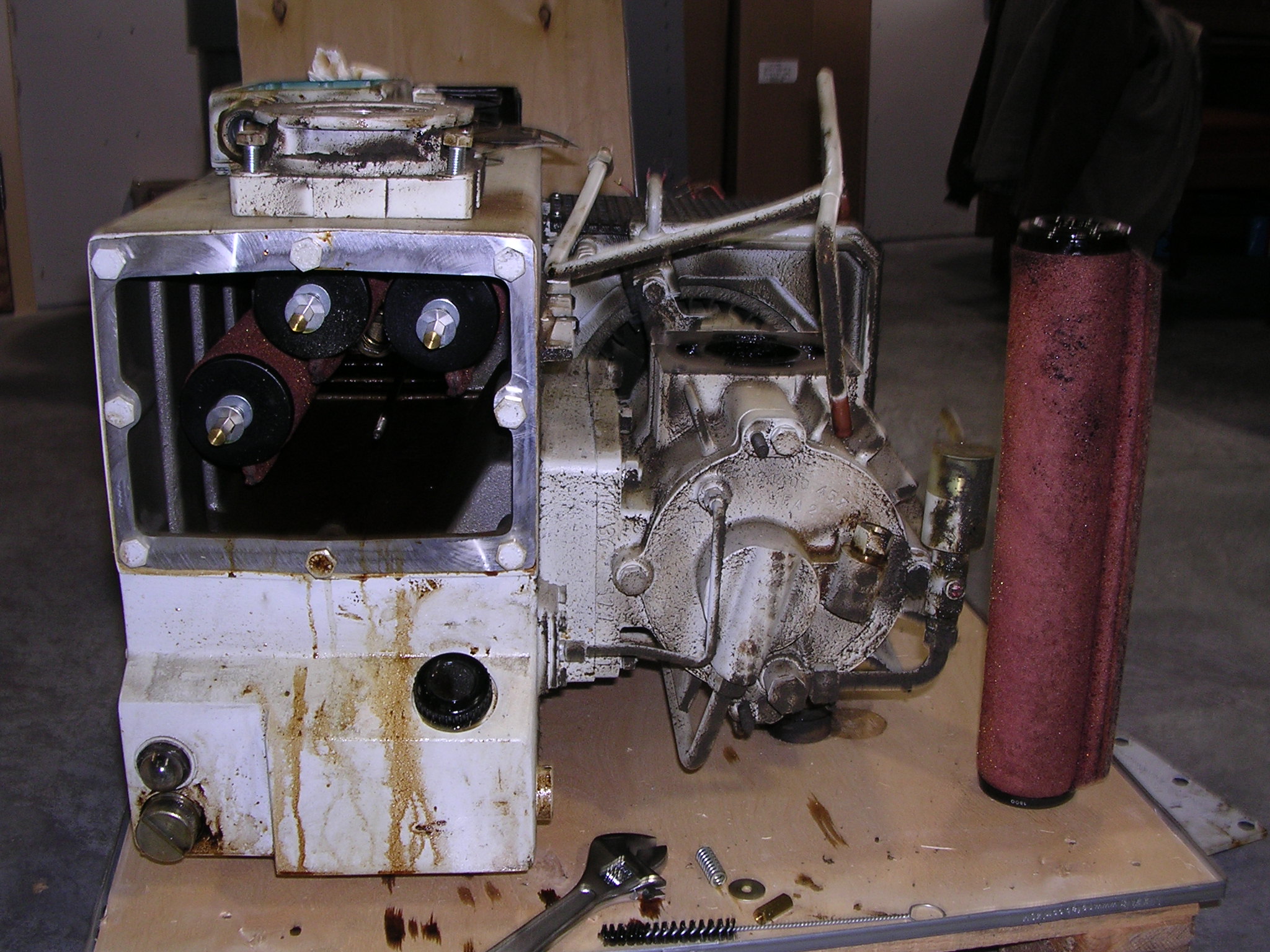

• Motor repair

• System updates, from complete overhaul to refurbishment

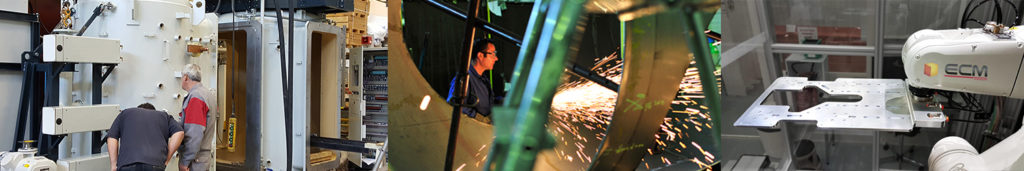

RETROFIT: Improve, Update and Adapt

RETROFIT: Improve, Update and Adapt

At ECM, our expertise and retrofit programs allow you to improve, update or adapt your furnace installation no matter what the brand is.

Increase process profitability by optimizing your installation. We maintain newer furnaces or older models - some with more than 45 years in production! This retrofit service conducted by ECM can be mechanical, electrical or both.

We strongly believe all of our customers will highly benefit from these improvements & updates.

USED FURNACES

ECM Technologies has an inventory of used ECM furnaces - and other brands as well. Considering a used furnace has numerous advantages:

• Budget conscious

• Cost optimization

• Commissioning optimization

• Reduced delays

• Update/Retrofit of the furnace

• All furnaces are reviewed by ECM Technologies

To view a current furnace inventory, please visit ecm-furnaces.com for more information.

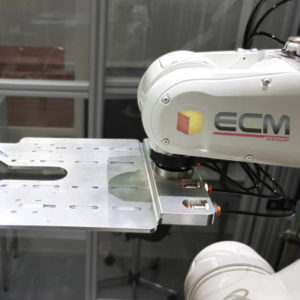

ROBOTICS

ROBOTICS

ECM Robotics is an ECM Group’s division that has the capacity to integrate and manage all kinds of robots for a wide range of applications. Its know how and services ensure the successful integration of robots in your production lines.

ECM Robotics innovates to offer the best experience for your project from its inception to its commissioning. To do so, the latest technology and innovations are involved. Virtual reality is used since the conception phase to “feel” the project since its premises, 3D printers are used to design prototypes (grippers) and 3D simulations are conducted to validate concepts and to simulate cycles.

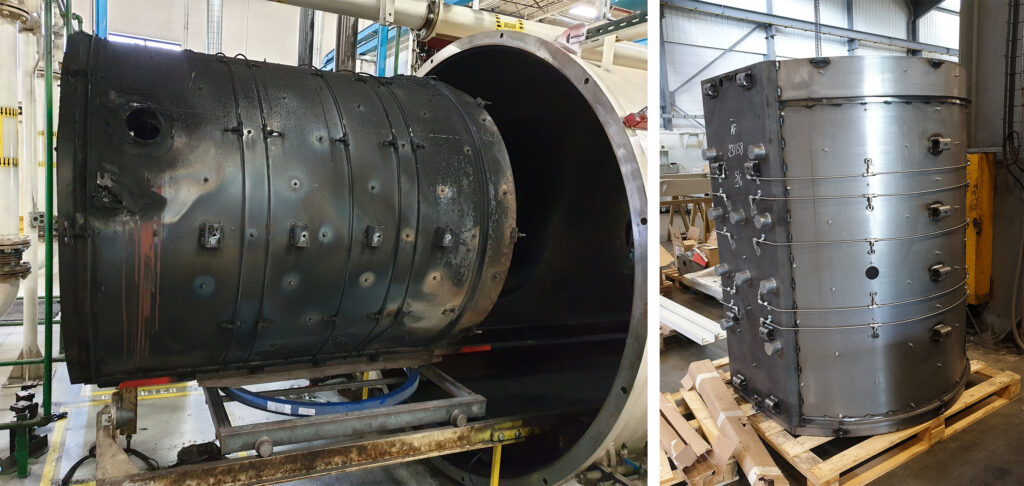

The hot zone, or casing, is the heart of any heat treatment system. Over time, its condition is the key to a reliable and consistent heat treatment batch. ECM USA stocks all the parts you need in order to help maintain your hot zones. With a lifetime between 7-10 years, dependent on furnace usage, its unique design allows our ECM service team to travel to your facility and change the full hot zone out in one day - minimizing equipment downtime.

The hot zone, or casing, is the heart of any heat treatment system. Over time, its condition is the key to a reliable and consistent heat treatment batch. ECM USA stocks all the parts you need in order to help maintain your hot zones. With a lifetime between 7-10 years, dependent on furnace usage, its unique design allows our ECM service team to travel to your facility and change the full hot zone out in one day - minimizing equipment downtime.

SYNERGY CENTER

SYNERGY CENTER

ECM USA’s Synergy Center is an R&D laboratory located in Pleasant Prairie, Wisconsin. It has been designed to solve all of your load testing needs! Bring your parts to ECM USA to test various low pressure vacuum carburizing, gas/oil quenching and loading scenarios – and receive on-site analysis of dimensional measurements and metallurgical results while you wait.

TRAINING

ECM USA offers a wide range of training for equipment provided to you in a complete, one source, turn-key heat treating solution. This service starts with training offered at our facility, or on-site at your production plant, to understand and learn how to operate our equipment and create recipes based on low pressure carburizing (carbonitriding, hardening, etc) treatment. At our Wisconsin facility, we also offer training based on metallurgical results from your heat treated parts. Testing can be completed in our on-site Synergy Center in order to compare your current process to the ECM LPC vacuum furnace.

On-site training capabilities:

- Operator training

- Electrical and mechanical maintenance

- Troubleshooting equipment software

- Sensor calibration

- TUS or leak detection