The ECM USA Synergy Center located in our North American headquarters in Pleasant Prairie, Wisconsin, showcases ECM equipment and provides pre-production testing. This fully functional test lab houses capabilities to perform many thermal processes across many markets.

The ECM USA Synergy Center located in our North American headquarters in Pleasant Prairie, Wisconsin, showcases ECM equipment and provides pre-production testing. This fully functional test lab houses capabilities to perform many thermal processes across many markets.

In this facility, customers are welcome to visit and work with ECM USA experts on their future test projects to confirm and evaluate thermal processes using actual production equipment. This effort is supported with years of ECM thermal process knowledge along with customer’s know how to produce a pre-production process. After this process is concluded, production equipment specifications can be assembled into full equipment proposal and budgets can be prepared.

For a complete list of our process capabilities, click on the Processes tab:

For a complete list of our process capabilities, click on the Processes tab:

• Low Pressure Vacuum Carburizing or Carbonitriding (gas and oil quenching)

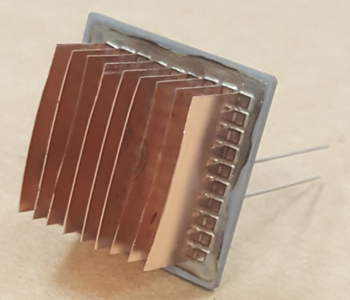

• Rapid Thermal Processing & Annealing

• Vacuum Tempering, Annealing, Brazing, Hardening

• Vacuum processes using Argon, Nitrogen, Helium and other process gases

• Low Pressure Vacuum Carburizing with gas and oil quenching

PROCESSES:

• Low Pressure Carbonitriding with gas or oil quenching

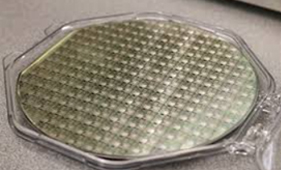

• RTP -Rapid Thermal Processing for electronic wafers

• RTA- Rapid Thermal Annealing of electronic wafers

• Vacuum Tempering

• Vacuum Annealing

• Vacuum Brazing

• Vacuum Hardening

• Tempering

• Annealing

• 3D additive stress relieve

• Vacuum processes using Argon, Nitrogen, Helium and other process gases

Other testing available using our parent facilities in Grenoble France:

• Crystal growth

• Robotics Lab

• VR simulation of complete installations

• VPA – Vapor Phase Aluminization

• Vacuum Induction Melting

SERVICES:

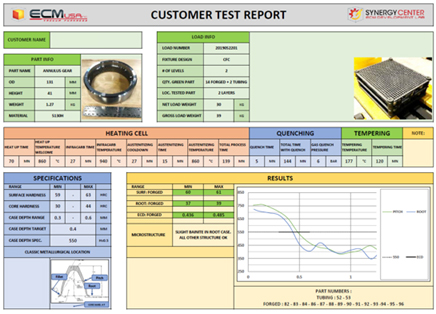

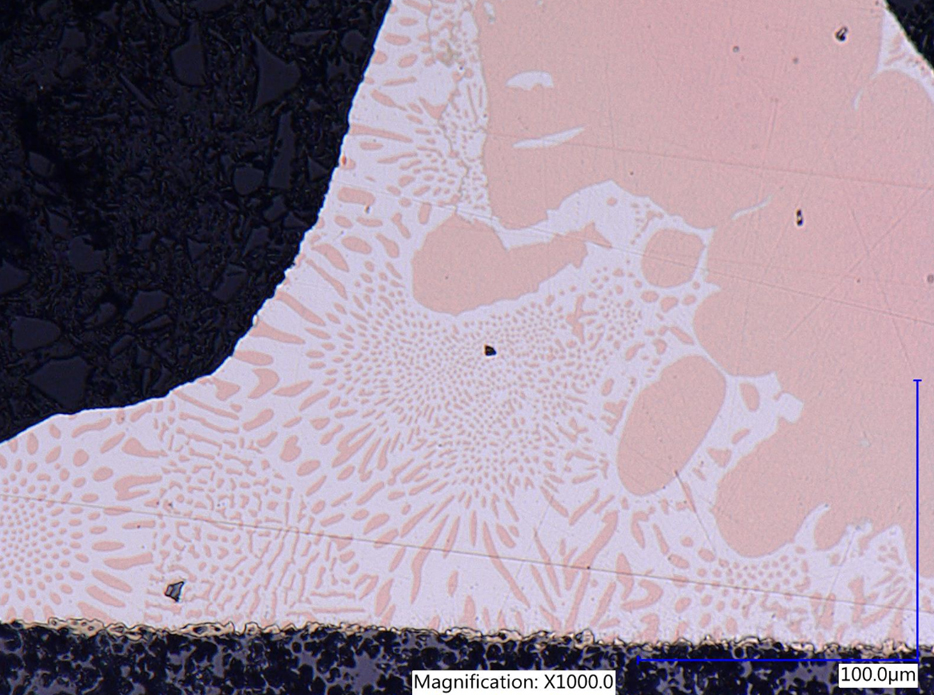

• Distortion control using CMM and 3D before and after thermal treatment

• Full Metallurgical evaluation of all test pieces

• Digital Microscope up to 5000 X

• Microhardness evaluation and contouring evaluation

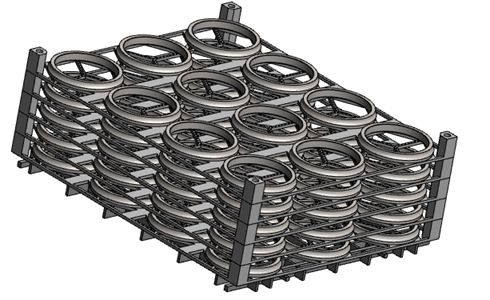

• Full production load Fixture design

• 3D Solidworks fixture design based on real-time thermal data

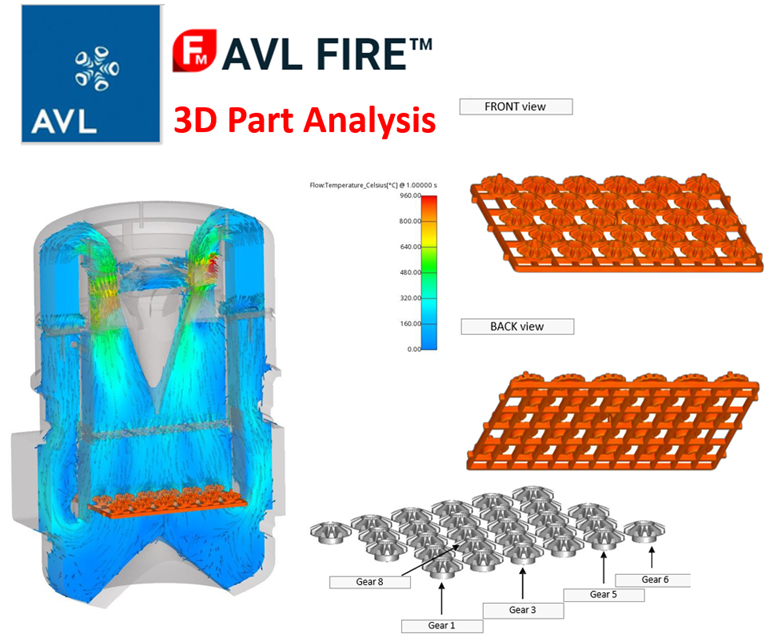

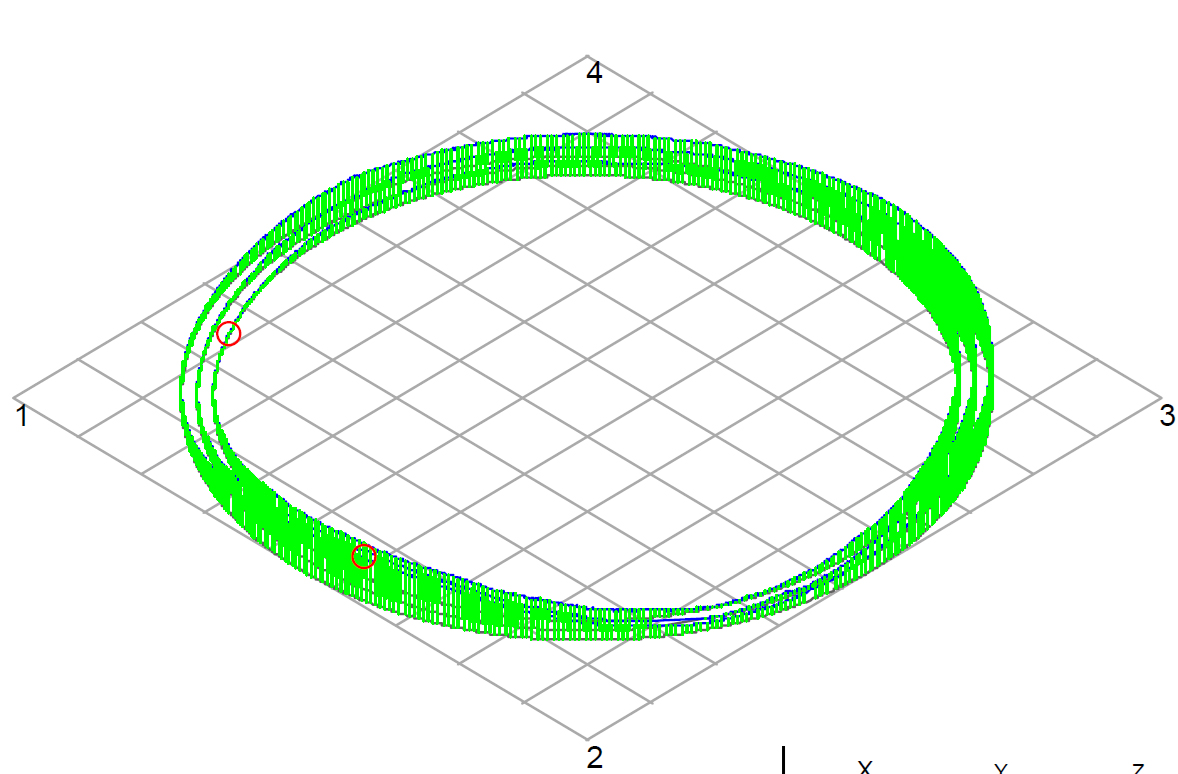

3D GAS QUENCHING EVALUATION:

3D simulation of parts within gas quenching during processing with AVL FIRE