BRAZING

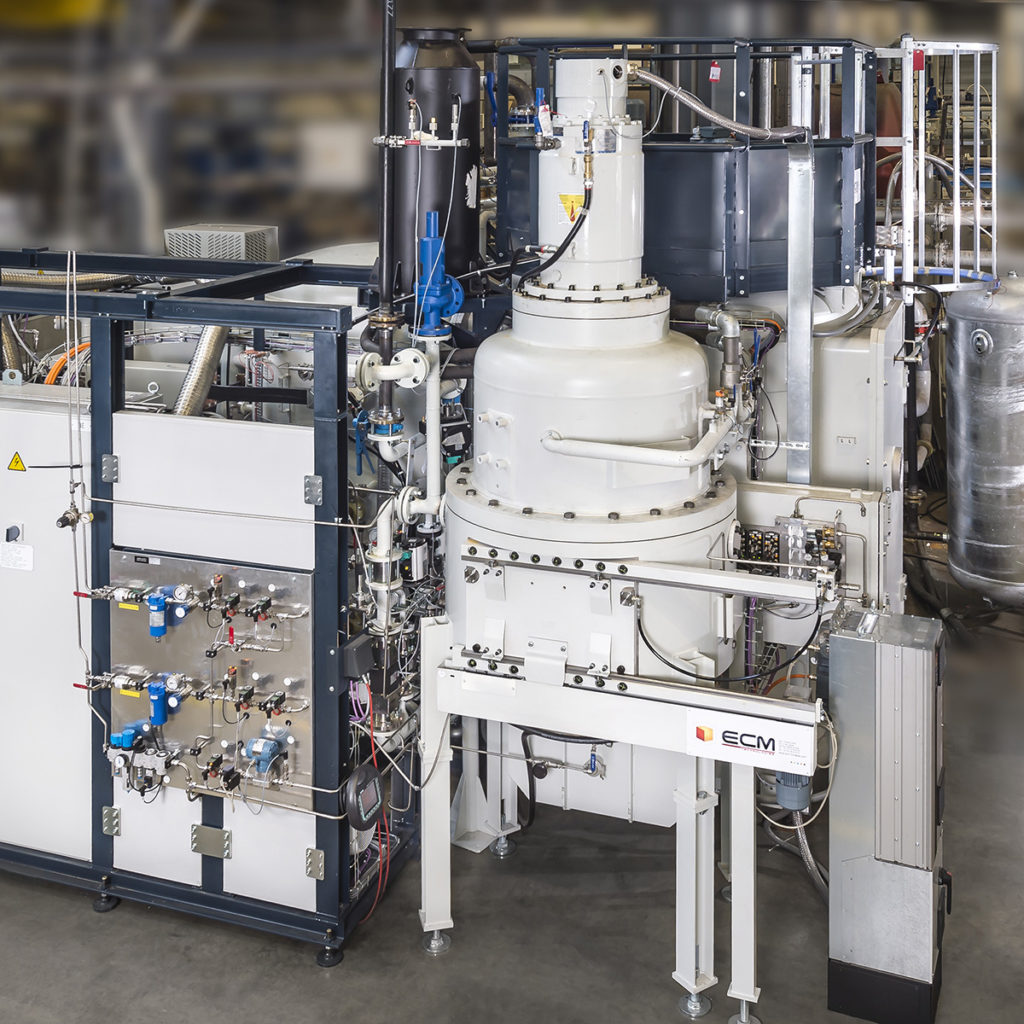

Our vacuum furnace solutions are offered with transfer systems that limit movement during the solidification phase. This ensures a premium quality treatment by reducing distortion and internal stresses. Moreover, the ECM range fulfills laboratory needs, as well as, industrial lines requiring high capacities - which allows us to adapt to various production flows and meet your process specifications.

Our vacuum furnace solutions are offered with transfer systems that limit movement during the solidification phase. This ensures a premium quality treatment by reducing distortion and internal stresses. Moreover, the ECM range fulfills laboratory needs, as well as, industrial lines requiring high capacities - which allows us to adapt to various production flows and meet your process specifications.

Our brazing solutions are dedicated to brazing under vacuum, inert gas or hydrogen.

By Definition, brazing is a process which consists in joining two metallic items by melting a filler metal used as a joint, such as copper, cobalt or nickel. This metal joining process takes place at high temperature, in a controlled atmosphere or under vacuum, to insure homogeneity and quality of the process.

There are several advantages to brazing with a low pressure vacuum furnace by ECM. It is a profitable process that easily fits in metallic parts production. Temperature homogeneity and the absence of oxygen ensure the full mechanical integrity of treated parts and of oxidation sensitive assembly at high temperature. Our solutions are apt to adapt to different atmospheres and required thermal profiles (heating speed, maintaining time, cooling speed). Moreover, pieces can be treated by batch, which alludes an increase in productivity and profitability.