Nuclear Applications

ECM’S DEDICATED NUCLEAR PROJECT TEAM is organized for a high level of confidentiality, operating under a normative framework based on project quality assurance plans (PAQP) with a dedicated quality inspector and installation designs adhering to nuclear codes & standards. The nuclear team works within a restricted access area and on an isolated local network.

ECM’S DEDICATED NUCLEAR PROJECT TEAM is organized for a high level of confidentiality, operating under a normative framework based on project quality assurance plans (PAQP) with a dedicated quality inspector and installation designs adhering to nuclear codes & standards. The nuclear team works within a restricted access area and on an isolated local network.

THERMAL SOLUTION SUPPLIER FOR COMPLEX PROCESSES & MATERIALS

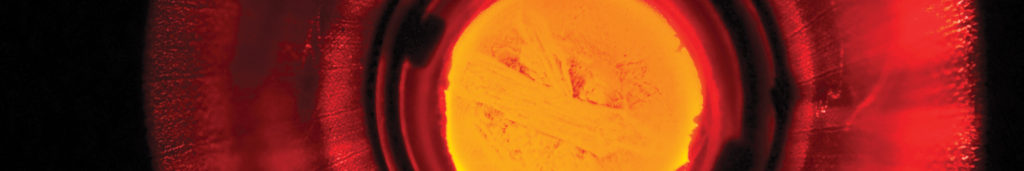

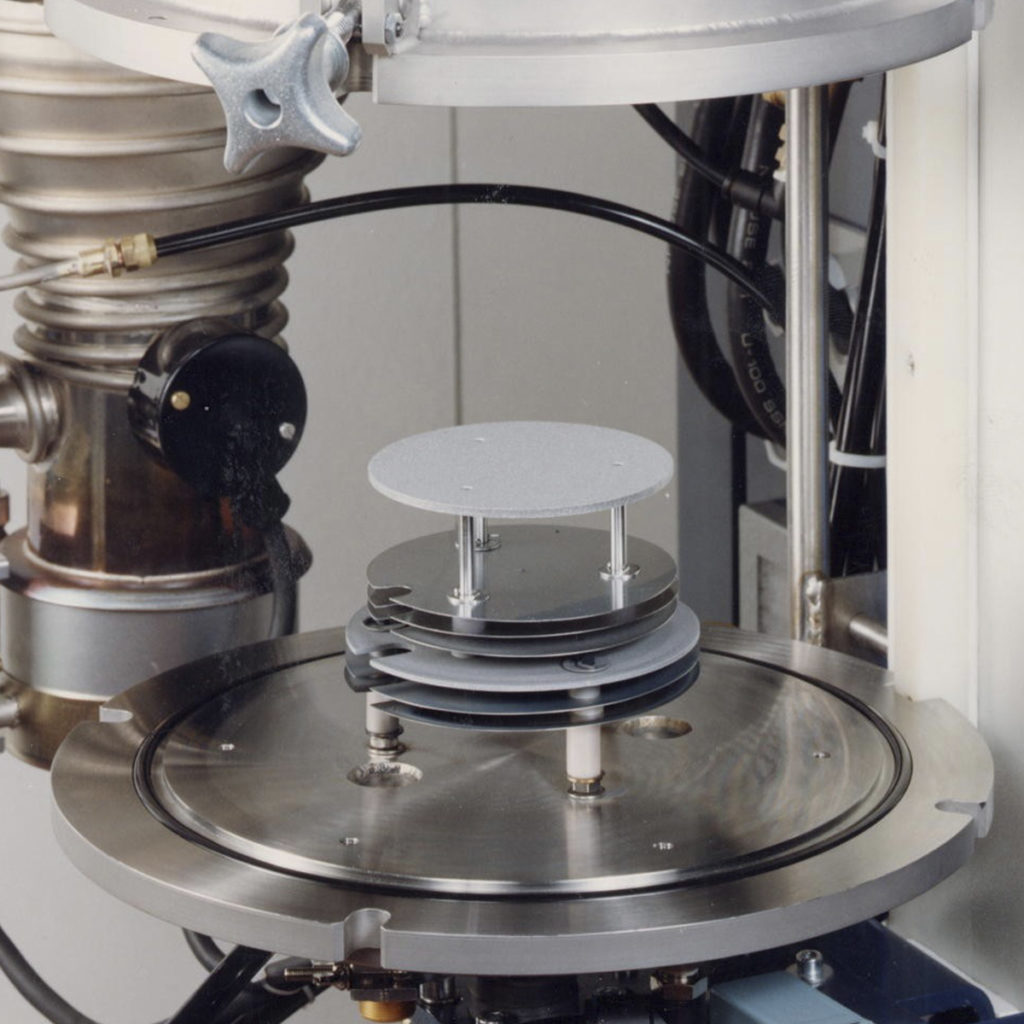

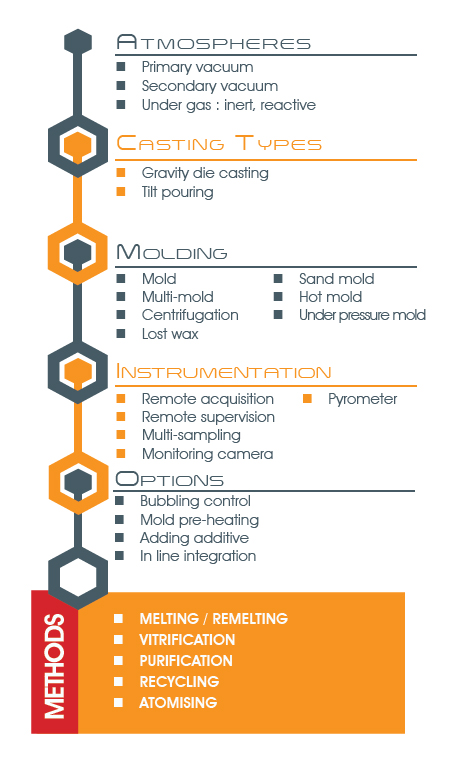

• Melting, vitrification, purification, brazing, degassing, calcination, reduction, annealing

• Treatment of different material types (powders, chunks, chips, pellets, ingots…)

• Controlled environment: furnace in gloveboxes, furnace in hot cells

EXPERTISE IN HIGH TEMPERATURES, HIGH PRESSURES & VACUUM ATMOSPHERE FOR THE ELABORATION OF MATERIALS

• Induction, arc, resistive heating adapted to meet your needs

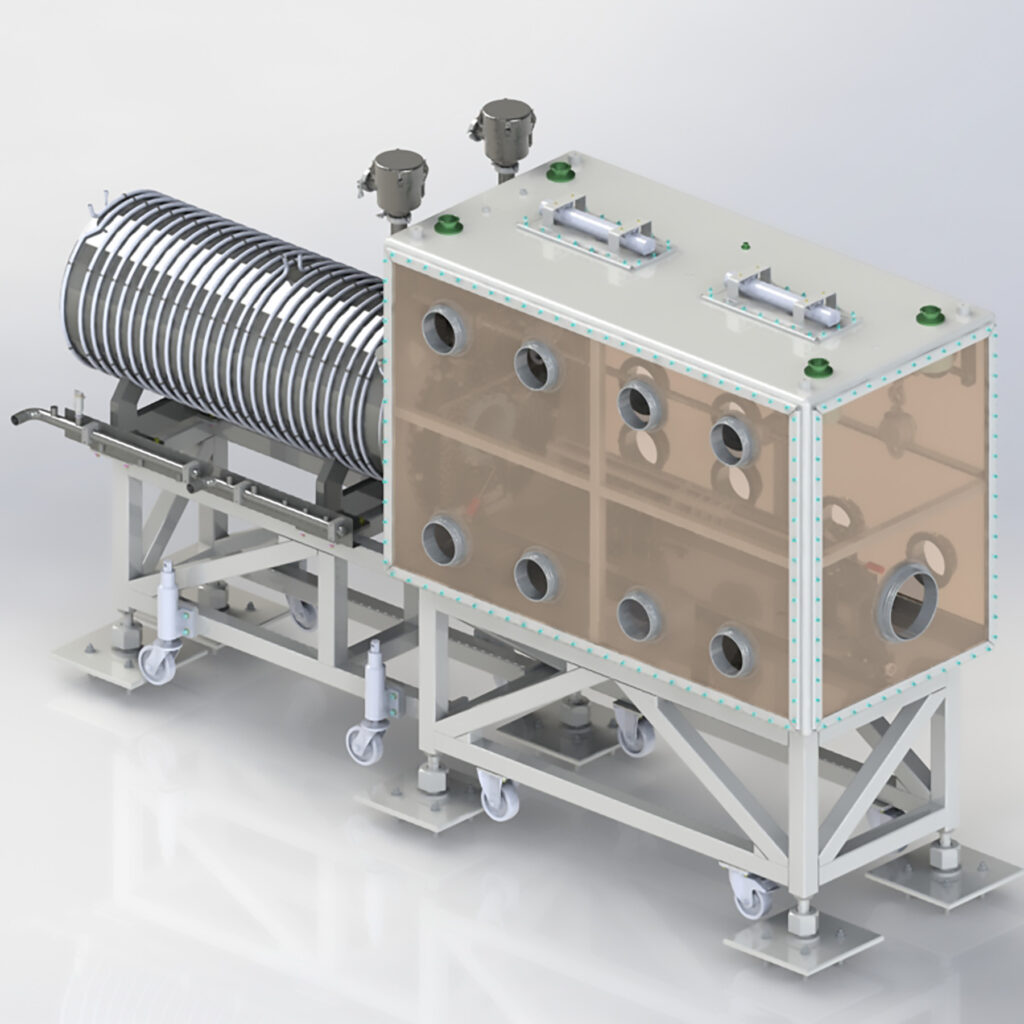

• Batch furnace, continuous line, rotary / screw / muffle furnaces, CCIM, etc

• Heating technologies up to 3000°C

• Vacuum & gas management (gas distribution, vacuum chambers, airlocks,…)

COLLABORATIVE PARTNERSHIPS

ECM takes a collaborative approach to meet specific requirements & standards within the nuclear industry and actively participate in the reinforcement of the French nuclear industry.

ENGINEERING

ECM has a division, dedicated to nuclear activities led by specially trained employees. For your large-scale multidisciplinary projects, we are recognized for our ability to unify and manage partners who are experts in their fields for a global and qualitative offer.

RESEARCH & DEVELOPMENT

ECM provides expertise in the management of complex processes, their associated instrumentation and their integration in glove boxes or hot cells. Our teams accompany the customers and partners from the preliminary design and definition phases, essential steps before undertaking the processes of execution studies and manufacturing.

MANUFACTURING

ECM integrates all the necessary skills for the manufacturing of the installation in its factories in Grenoble. Our teams are also trained for set-up, on-site installation, manufacturing follow-up, staff training and test assistance.

SERVICE & AFTERSALES

ECM offers a wide range of solutions with our continuous improvement service program: assembly, commissioning, installation, on-site maintenance, training, relocation, retrofits, and upgrades.

• Zr tube annealing furnace

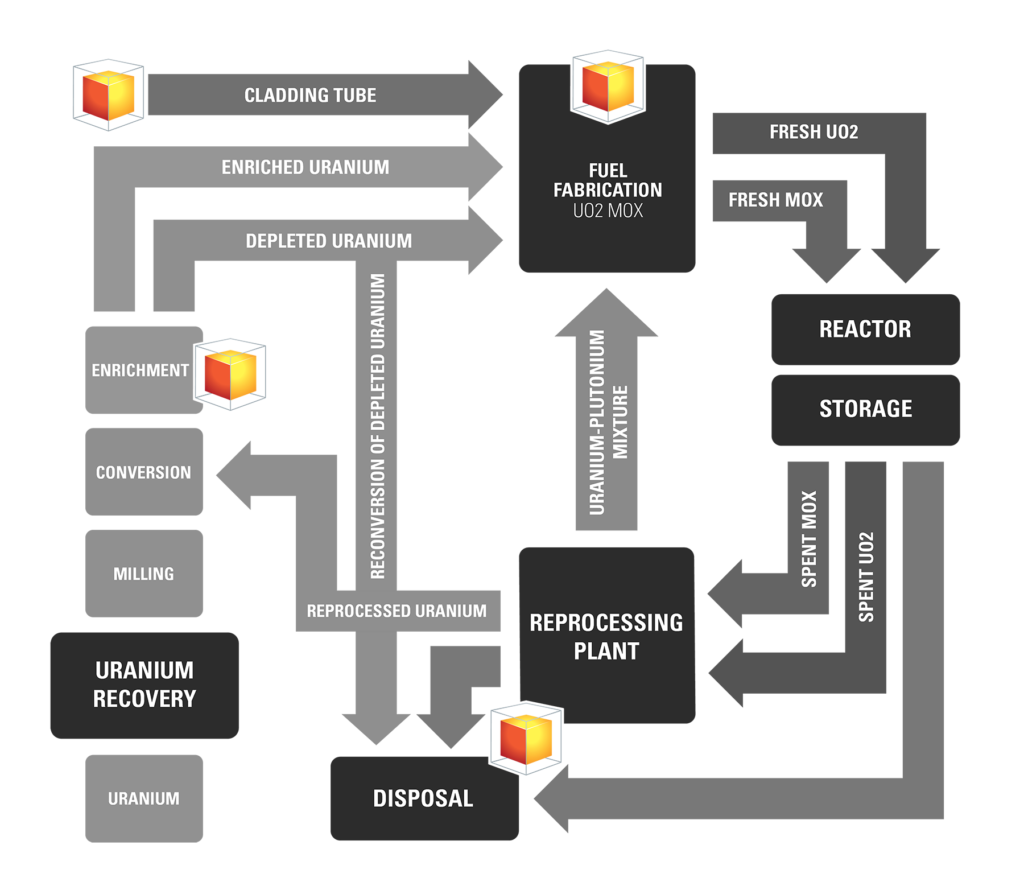

• MOX & U02 fuel sintering furnace

• Calcination & reducing powder furnace

• Vitrification furnace

WASTE MANAGEMENT

CALCINATION / DEGASSING

FURNACES IN GLOVEBOX

• For volume reduction, degassing…

• Batch retort furnace (or induction melting) in glovebox

• Vacuum or gas atmosphere (O2 for calcination)

• Interface with or integration in glovebox

• Off-gas treatment

• Custom-made solutions according to customer

specifications