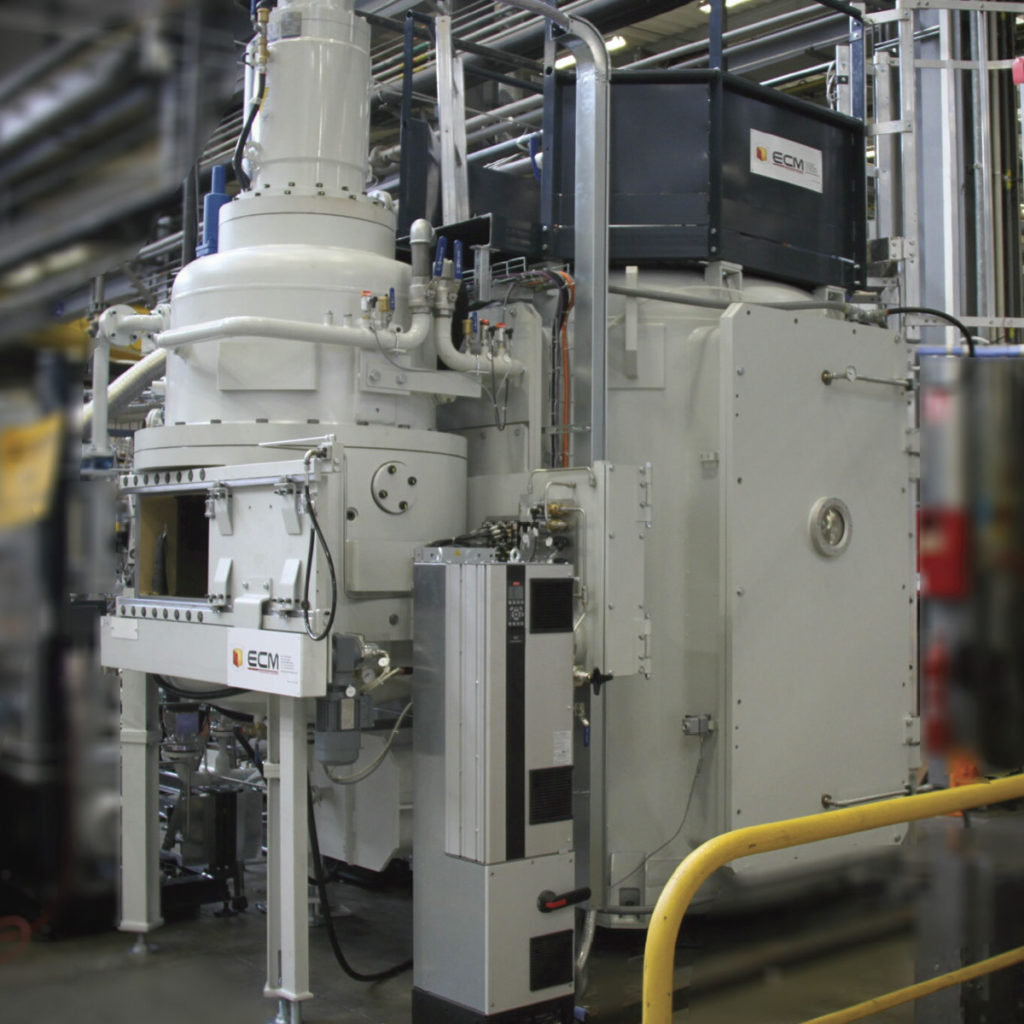

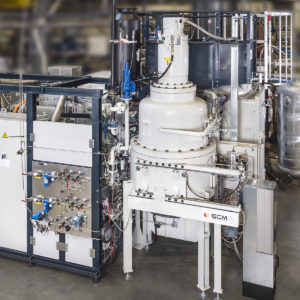

Nano Vacuum Furnace

The ECM Nano vacuum furnace is the latest product in the range of Low Pressure Carburizing and carbonitriding furnaces, which uses technologies already proven on over 200 installations and 1000 ICBP® heating cells through out the world. The Nano vacuum furnace system is comprised of one module with 3 stacked up heating cells (which can be extended to 6 heating cells, corresponding to 2 heating modules) and gas quenching cells to quench the parts. The carburizing cells are stacked up to reduce the footprint’s installation as much as possible. The Nano furnace system integrates directly into the production line which allows it to reduce the cycle time while simplifying the flow between the machining and heat treatment.

Nano 600 TG Maintenance Rendering - easy and efficient

Flexibility

• Add 3 extra heating cells on an existing installation to increase production capacity

Guaranteed Performance

• Optimal performance due to our test platform and integrated metallurgy laboratory

Improved Productivity

• Directly integrate into the machining line.

• Shorter treatment cycles (possible speed: 1 load / 7.5 mm)

Shorten on-site installation time

• The equipment is completely assembled and tested before shipment with minimal disassembly/reassembly and to shorten start-up.

• Vacuum Carburizing

• Vacuum Carbonitriding

• Hardening

• High Temperature Tempering

• Vacuum Annealing

• Brazing

• Sintering

| Specifications | |||

| Gross Load | Width | Height | Length |

| 100kg | 500mm | 250mm | 600mm |

Options

• Up to 6 stacked cells