Sintering

On contrary to traditional metallurgical processes that solidify melted metals, powder metallurgy starts with metallic powders that are solidified, thanks to a sintering process. This process can be realized during a solid phase or transient liquid phase bonding. When occurring in transient liquid phase bonding, a liquid phase happens when the sintering temperature exceeds the melting point of one of the components of the powder. This is the case of copper based steels.

Before the sintering step, a first shape is produced during a compression phase, usually taking place when cold. To do so, a mix of elementary powders (or allied) and a lubricant is dropped in a matrix taking the shape of the part to be produced. Once compressed, the part has a very limited mechanical strength, but still can be easily handled with caution. It is the sintering process which, thanks to a material transfer phenomenon, will reduce the parts’ porosity and give the parts their final mechanical strength. The indentation observed during the sintering phase has to be taken into consideration when designing the matrix. The mastering of this step allows to get pieces that are near to net shape, allowing to avoid costly machining operations.

Most of the time, sintering is realized using conveyor furnaces. This technology allows continuous loading with presses in line. Parts go through three steps when going through the furnace. The first part of the furnace is dedicated to the disposal of joining parts with working temperatures comprised between 300°C and 600°C. The second part of the furnace is dedicated to the sintering process, which is conducted in between 1120°C and 1135°C. This process can take 10 to 30 minutes. The last part of the furnace is dedicated to cooling. Cooling speed can go from 0,5°C up to 5°C per second according to the systems used.

Higher temperature sintering (1200°C-1300°C) requires different furnaces technologies such as walking beam furnaces. This technology is often needed to sinter chrome-containing shades, which are very sensitive to the presence of oxygen within the sintering atmosphere. However, this technology is more costly and the life cycle of conveyors can be highly reduced.

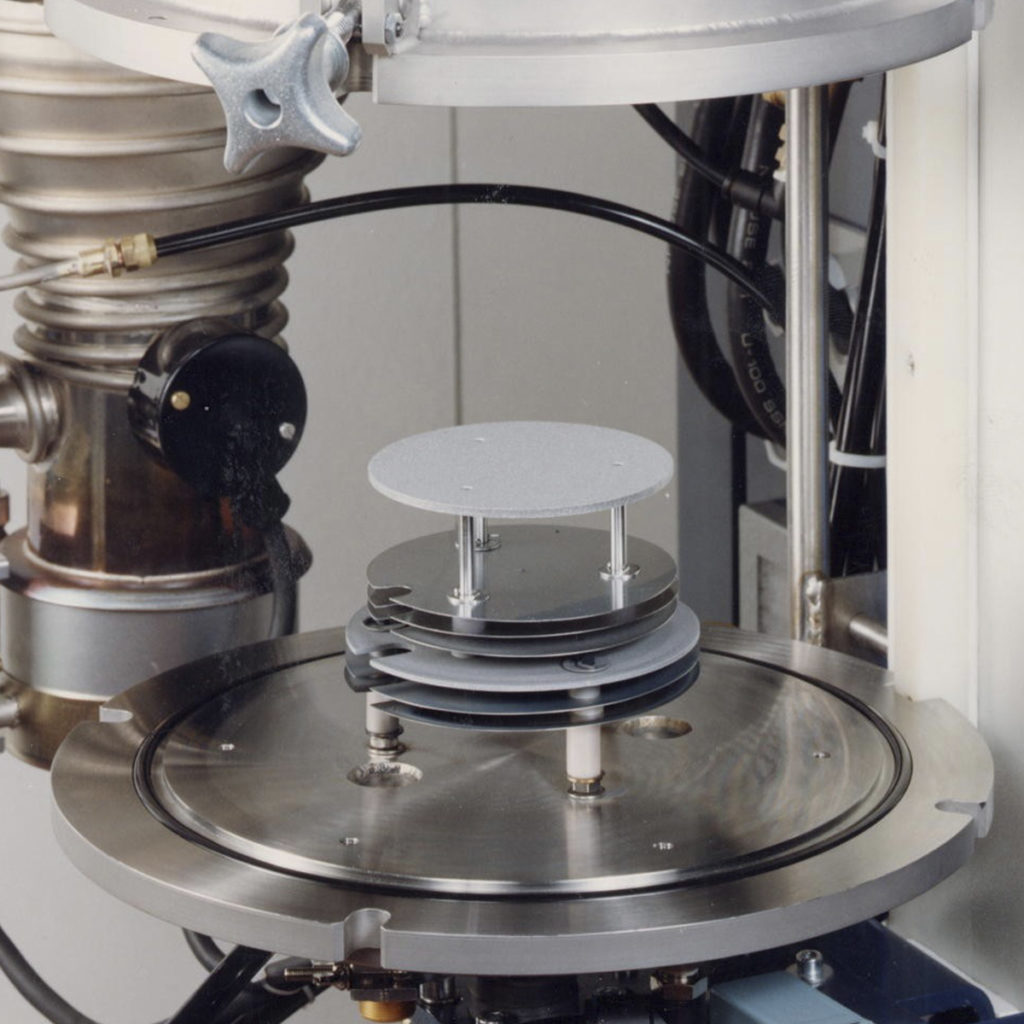

Technologies of vacuum furnaces allows to get rid of the use restrictions of conveyor furnaces. Indeed, parts can be sintered at high temperature, with perfect control over the sintering atmosphere. The absence of oxygen allows to sinter shades that are very sensitive to oxidation. Moreover, associated to gas quenching, this type of furnace allows to cool down pieces way faster than when using conveyor furnaces.

Finally, when a final carburizing phase is required, this technology allows a flawless transition between the sintering phase and the low pressure carburizing one, without any interruption. Thus, thanks to this “all-in-one” cycle (debinding, sintering, carburizing & quenching) within the same furnace, cycle times can be highly reduced.