Nitriding

Nitriding is a thermochemical treatment that diffuses nitrogen into the surface of metals. It is used on ferrous, titanium, aluminum, and molybdenum alloys, but most commonly on low-carbon, low-alloy steels. It improves surface properties of metal components and tools such as abrasion and corrosion resistance, and increases the fatigue strength. Typically carried out at 450 to 520°C, nitriding is generally considered a lengthy process (depending on the case depth requirements) which can take from 4 to 60 hours or more. The number of parts (mass of the load) may affect how long it takes the furnace to get up to the required temperature but does not affect nitriding soak time. This treatment is below the tempering or stress-relieving temperatures of steel, which are over 600°C. Therefore, the process causes little or no distortion. Nitriding can be treated as a final operation in most situations. Post-nitriding polishing can be applied if a super-low surface roughness is required. Nitriding does not change part weight, but parts may grow a little—about 0.001-0.005 mm on a diameter of about 50 to 80 mm. Growth is predictable and repeatable. The ECM vacuum purged gas nitriding process increases the surface hardness as well as abrasion and wear resistance. It also improves bending and/or contact fatigue properties. Rolling contact fatigue time-to-failure can be increased by several orders of magnitude depending on material. Nitriding can also decrease a part’s coefficient of friction. In addition, the process forms a thin, corrosion-resistant layer of iron oxide/magnetite, which significantly increases corrosion resistance. Bending, torsional and rolling contact fatigue resistance are also increased. Many of the part surface improvements are results of increased compressive stresses. The vacuum purge capability of the ECM furnace ensures there can be no ammonia smell within your facility making this a clean, safe and ergonomic process as compared to the traditional atmosphere based nitriding process. OUR NITRIDING FURNACES ADVANTAGES• Excellent quality and repeatability of treatments

|

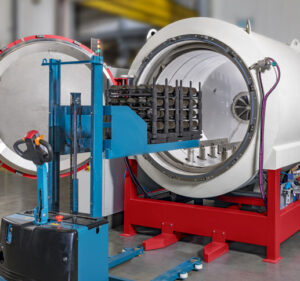

VESUVE NITRIDING FURNACE

VESUVE NITRIDING FURNACE